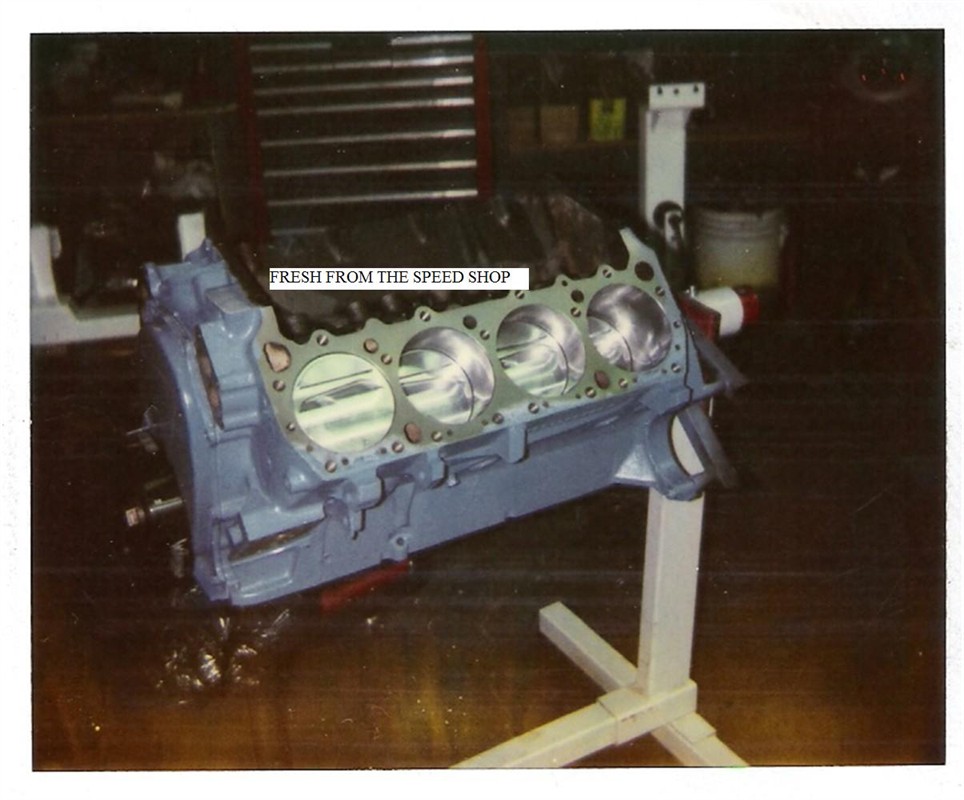

Advisors at the speed shop recommended a piston with a turbulence producing "squish" area. The CCMI engine was produced with the beefier "6-pack" rods. They were cleaned up (de-bured and polished in critical areas) and then shot peened for stress relief. The forged crank and dynamic components are balanced. The stock (and most likely detuned) harmonic damper was replaced with a fluid-damper. |

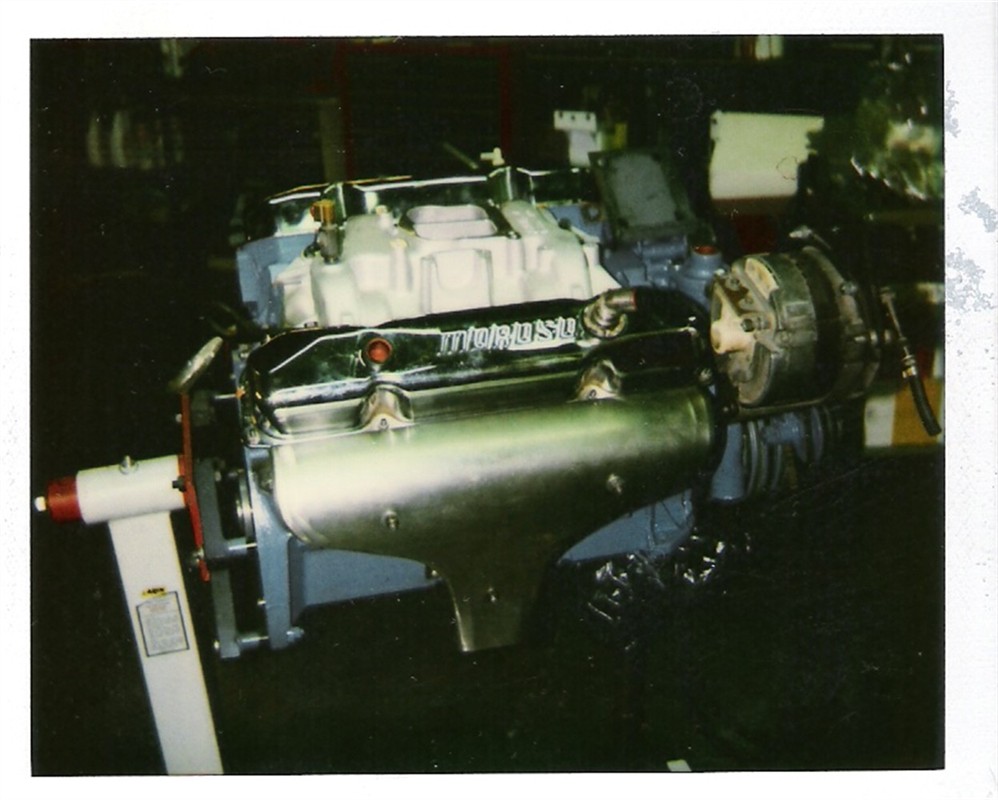

Spread bore Edelbrock induction manifold with #1905 "Q-Jet" carburetor. (not shown/no longer available.) Heat shield keeps engine compartment temp. down and manifold heat away from rocker box gasket. Gasket is hi-temp Fel-pro. |

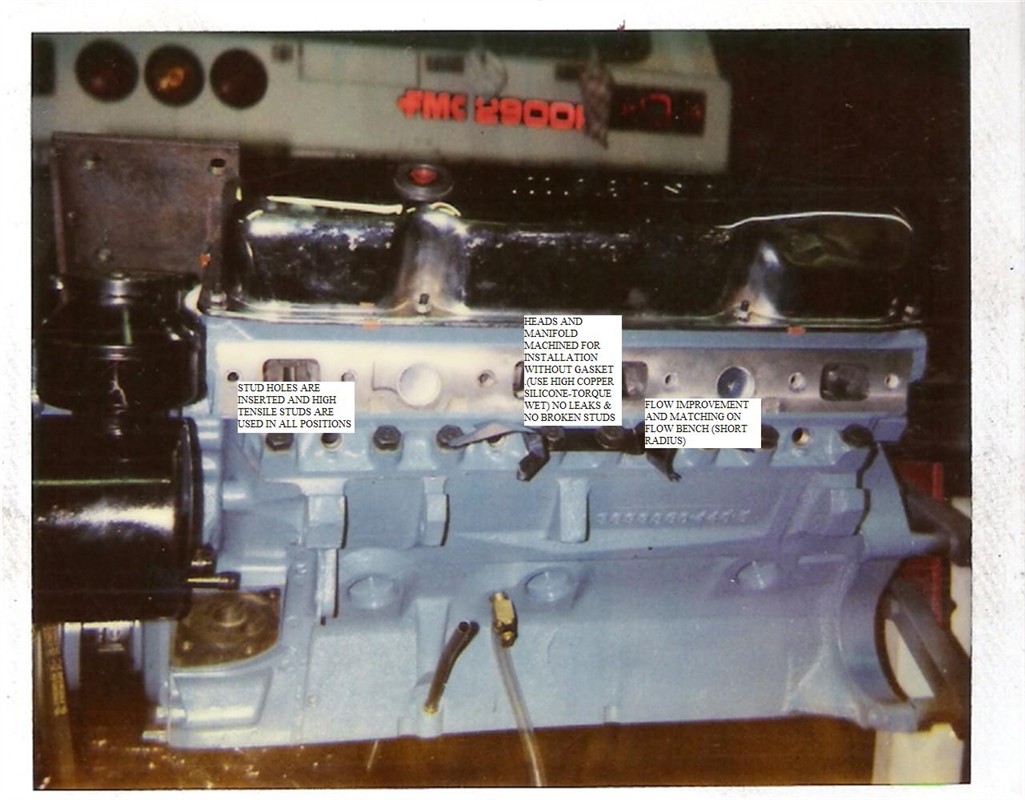

Heads are modified with hard valve seat inserts,new valve guides, thread inserts for the exhaust studs, high tensile studs,machined rocker box gasket surfaces as well as exhaust manifold surfaces for installation without gaskets for superior heat transfer etc.. Friends at the speed shop matched all ports on the flow bench and cleaned up the short radius enough to improve flow somewhat. |

Note the stainless shield between the manifold and the block to keep heat from the water jacket. |